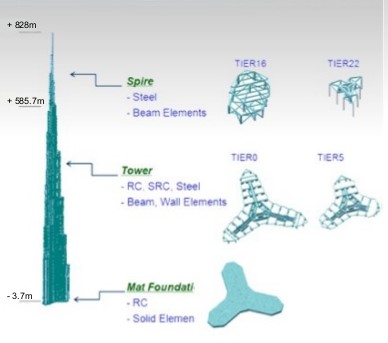

The tower superstructure of Burj Khalifa is designed as an all reinforced concrete building with high perfomance concrete from the foundation level to level 156, and is topped with a structural steel braced frame from level 156 to the highest point of the tower.The high-performance concrete used in Burj Khalifa guarantee low permeability and higher durability.The C80 and C60 cube strength concrete is used incorporating fly ash, Portland cement, and the local aggregates. A young’s modulus of 43800N/mm2 is said to be granted by the C80 concrete.The largest concrete pumps in the world were used to pump concrete to height up to 600 m at a single stage. Two numbers of this type of pump was used.As the temperature of the location (Dubai) is very high, there were chance of cracks due to shrinkage. So, the concrete pouring process was carried out at night at a cooler temperature. Ice was added to the concrete mix to facilitate the desired temperature.To withstand the excessive pressure caused due to the building weight, special concrete mixes were employed. Every batch was tested before placing.The structure of Burj Khalifa was designed to behave like a giant column with cross-sectional shape that is a reflection of the building massing and profile.